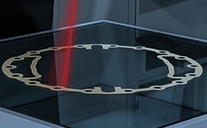

Precision die cutting is a process of converting sheets or rolls material into custom gaskets and other die cut parts with speed, uniformity, and accuracy. Plus, it’s cost-effective over a wide range of part sizes and quantities.

Interstate Specialty Products provides custom precision die cutting services that support tight tolerances, small and large part sizes, and various production volumes. Here, at our Made in the USA manufacturing facility in Sutton, Massachusetts, we use high-quality tooling and state-of-the-art equipment to convert a wide range of non-metallic materials. We also offer rotary die cutting, digital knife cutting, slitting & laminating, cleanroom converting, and component prototyping services.

Advantages of Precision Die Cutting

Precision die cutting is fast, consistent, and cost-effective for parts that range from miniature washers to large gaskets. Non-metallic materials are continuously fed into die cutting equipment, and parts with tight tolerances are continually output. These die cut parts have a high degree of uniformity, even across high production volumes. Part features such as punched holes with specific radii are readily achievable in production runs that range from dozens to millions of parts. Interstate can also combine precision die cutting with specialized handling and conversion capabilities, including the application of pressure-sensitive adhesives (PSAs) for peel-and-stick parts.

Digital Cutting Solutions: 5 Questions for Determining the Best Manufacturing Process

Discover the best cutting method for manufacturing your components by considering important factors like lead-times, part formatting, and more.

Part Tolerances and Precision Die Cutting

Die cutting tolerances aren’t just a function of die type or part size. Material type, part features, tool type, and production technique play an important role. Tool costs, turnaround times, and specific design and manufacturing advantages also vary by precision die cutting technique.

Choose Precision Die Cutting from Interstate

Precision die cutting isn’t just about high-quality tooling and state-of-the-art technology. With over 50 years of die cutting expertise, Interstate adds application knowledge and technical expertise to your project. To learn how our custom die cutting capabilities can support your specific application, contact us on-line or call (800) 984-1811.

*Properties and applications shown throughout this website are typical. Your specific application should not be undertaken without independent study and evaluation for suitability.