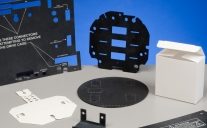

Interstate Specialty Products die cuts thermal management silicone for medtech, electronics, and industrial applications.

For over 60 years, our Made in the USA manufacturing company has been die cutting silicone insulation at our custom fabrication facility in Sutton, Massachusetts.

Learn about the different types of thermal management silicone, and how custom silicone insulation is manufactured.

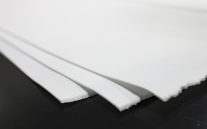

Types of Silicone Insulation

Silicone insulation includes thermally-conductive pads and gap fillers that provide high thermal diffusivity and heat resistance. Both types of silicone insulation are used in heat sinks, which transfer or remove heat produced by electronic equipment. Softer silicone insulation can be used where the interface between an electronic device and heat sink is rough, or not co-planar enough to remove air gaps or compensate for misalignment. Silicone with excellent elastic properties provides strong cushioning, and helps to insulate electronic components such as transistors against damage caused by deformation, shock, or vibration.

How Custom Silicone Insulation Is Manufactured

Silicone insulation for thermal management can be reinforced with fiberglass cloth or nylon mesh, and supplied as sheets, rolls, extrusions, or moldings. Interstate Specialty Products uses die cutting or roll slitting techniques to custom-manufacture silicone insulation to your exact specifications.

To learn how our silicone insulation manufacturing capabilities can support your application, contact us online or call (800) 984-1811.

*Properties and applications shown throughout this website are typical. Your specific application should not be undertaken without independent study and evaluation for suitability.