Advantages of Porex Virtek® PTFE Membranes

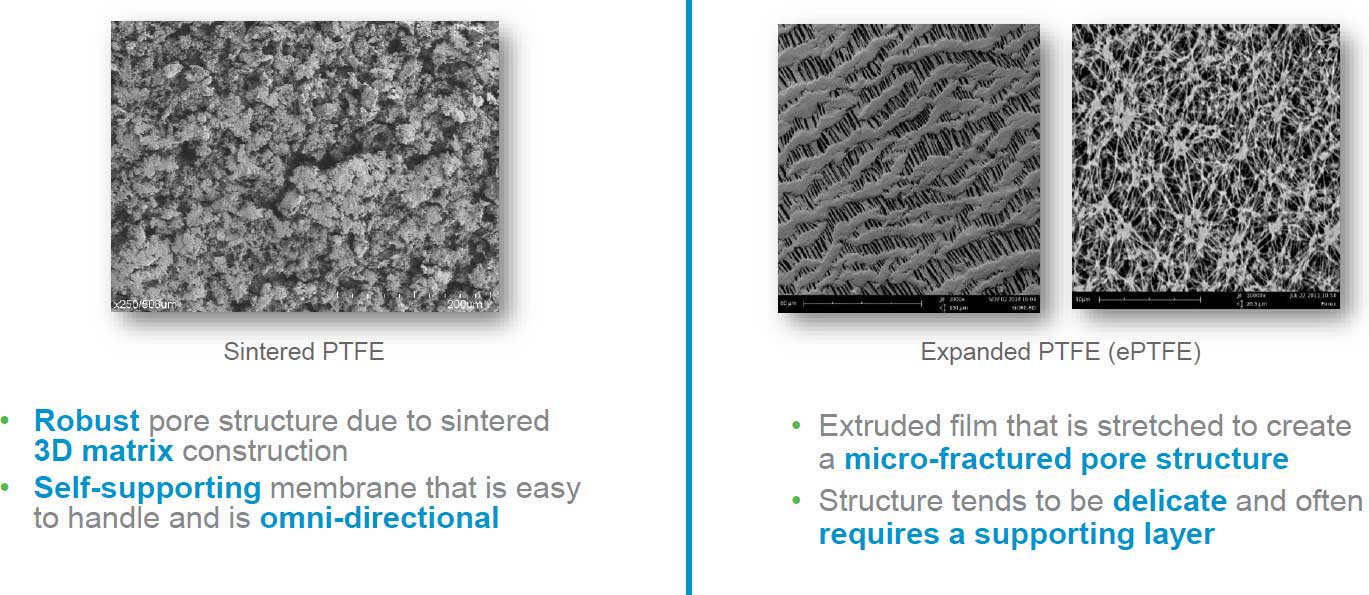

- Robust and durable sintered PTFE due to 3D matrix construction

- Naturally hydrophobic for waterproof venting

- Self-supporting membrane that is easy to handle and omni-directional

- UL-94 flammability and UL-746C weatherability

- Reflective properties to diffuse light or radiation

Sintered PTFE vs. ePTFE Membranes

Proper diffuse reflectivity is critical in uniformly distributing light energy. This is particularly critical in UVC disinfection devices.

Healthcare applications may include filters for sterilization containers that need to resist microbe entry yet allow steam heat to penetrate into the box to fully sterilize the equipment.

Applications include electrical enclosures, container venting, diagnostic & medical venting, and more. Porex Virtek is the material of choice for durable and reliable venting.

Porex Virtek PTFE membrane is unaffected by virtually any chemical. This is important when supporting other media such as in chromatography applications.

Having optimal dielectric properties is critical in products such as antennae systems. Porex Virtek PTFE membrane can attain a consistent dielectric constant while maintaining tight thickness tolerances.

Applications for Porex Virtek® :

Reflectivity:

Proper diffuse reflectivity is critical in uniformly distributing light energy, especially in UVC disinfection devices.

Filtering:

Medtech applications may include filters for sterilization containers that must keep out microbes but let steam heat in to fully sterilize equipment.

Venting:

Applications include electrical enclosures, container venting, diagnostic & medical venting, and more. Porex Virtek® is the material of choice for durable and reliable venting.

Media Support:

Porex Virtek® membrane is unaffected by virtually any chemical. This is important when supporting other media such as in chromatography applications.

Dielectrics:

Having optimal dielectric properties is critical in products such as antennae systems. Porex Virtek® PTFE membrane can attain a consistent dielectric constant while maintaining tight thickness tolerances.

1 Can be Oleophobically treated to Grade 8 by AATCC TM 118-1997

| Item Number | IP Rating | WEP* mbar(Typical | Typical Airflow l/hr/cm² @70mbar |

Filtration Efficiency* >99.99% |

Thickness mm | Max Operating Temp °C |

Salt Fog$ |

|---|---|---|---|---|---|---|---|

| PMA10‡ | 64,67 | 370 | 75 | 0.4 µ | 0.18 | 260 | No pen. |

| PMA15‡ | 65,67,68 | 520 | 25 | 0.1 µ | 0.25 | 260 | No pen. |

| PMA20‡ | 65,66,67,68 | 1050 | 7 | 0.1 µ | 0.19 | 260 | No pen. |

| Porex Virtek – General Puropse Venting product range (hydrophobic) | |||||||

| PMV10 | 64,67 | 270 | 107 | 0.5µ | 0.13 | 260 | No pen. |

| PMV10L*** | 64,67 | 270 | 85 | 0.5µ | 0.3 | 100 | No pen. |

| PMV15 | 64,67 | 370 | 75 | 0.4µ | 0.18 | 260 | No pen. |

| PMV15T‡ | 64,67 | 370 | 75 | 0.4µ | 0.18 | 260 | No pen. |

| PMV20 | 64,65,68 | 520 | 25 | 0.1µ | 0.25 | 260 | No pen. |

| PMV25 | 65,67,68 | 765 | 17 | 0.2µ | 0.1 | No pen. | |

| PMV27 | 65,66,67,68 | 1050 | 7 | 0.1µ | 0.19 | 260 | No pen. |

We encourage you to contact our team for detailed specifications

*WEP = Water Entry Pressure

$ ASTM B117-11 test method

*** Laminated polyolefin mesh backing

‡ Oleophobic, AATC TM 118- Grade 8

Porex Virtek – General Puropse Venting product range (hydrophobic)

*WEP = Water Entry Pressure

$ ASTM B117-11 test method

*** Laminated polyolefin mesh backing

‡ Oleophobic, AATC TM 118- Grade 8

| Material | Thickness mm Nominal |

Typical Airflow l/hr/cm2 at 70 mbar |

BFE* % Nominal |

VFE** % Nominal |

Typical WEP*** mBar |

|---|---|---|---|---|---|

| MD10 | 0.13 | 107 (min 70) | >99.9 | † | 270 (min 175) |

| MD10L | 0.3 | 85 (min 48) | >99.99 | † | 270 (min 175) |

| MD15 | 0.18 | 75 (min 45) | >99.99 | † | 370 (min 265) |

| MD20 | 0.25 | 25 (min 16) | >99.9999 | >99.999 | 520 (min 350) |

| MD25 | 0.19 | 7 (min 2) | >99.9999 | † | 1050 (min 750) |

***WEP = Water Entry Pressure

**According to IEST RP-CC007.2 2009

***WEP = Water Entry Pressure

**According to IEST RP-CC007.2 2009

| Product Number | Min. Airflow l/hr/cm2 at 70 mbar |

Typical Airflow l/hr/cm2 at 70 mbar |

Min WEP* mBar |

Typical WEP* mBar |

Thickness mm | Max Operating Temp °C |

Dry Filtration Efficiency* >99.99% |

|---|---|---|---|---|---|---|---|

| BM10 | 14 | 30 | 200 | 360 | 1.0 | 260 | |

| BM15 | 25 | 84 | 30 | 120 | 1.0 | 260 | |

| BM20 | 50 | 90 | 10 | 80 | 1.0 | 260 | |

| BM25* | 11 | 20 | 200 | 400 | 1.5 | 260 | |

| BM30 | 16 | 50 | 120 | 200 | 1.5 | 260 | |

| BM35 | 25 | 60 | 40 | 140 | 1.5 | 260 | |

| BM40* | 25 | 55 | 20 | 100 | 1.5 | 260 | |

| BM45 | 8 | 18 | 220 | 430 | 2.0 | 260 | |

| BM50 | 16 | 40 | 80 | 200 | 2.0 | 260 | |

| BM55 | 18 | 50 | 50 | 180 | 2.0 | 260 | |

| BM60* | 25 | 50 | 20 | 140 | 2.0 | 260 | |

| BM65 | 6 | 12 | 250 | 450 | 3.0 | 260 | |

| BM70 | 14 | 32 | 90 | 230 | 3.0 | 260 | |

| BM75* | 14 | 35 | 70 | 245 | 3.0 | 260 | |

| BM80 | 15 | 40 | 20 | 200 | 3.0 | 260 | |

| BM105 | 1 | 2.5 | 800 | 1000 | 1.0 | 260 | 0.1µ |

| BM110 | 0.75 | 2 | 800 | 110 | 1.5 | 260 | 0.1µ |

| BM115 | 0.5 | 2 | 820 | 1150 | 2.0 | 260 | 0.1µ |

| BM120 | 0.25 | 1 | 840 | 1400 | 3.0 | 260 | 0.1µ |

* Items currently stocked at Interstate

* Items currently stocked at Interstate

| Porex PTFE Product | Thickness (In) | Thickness (MM) | ||

|---|---|---|---|---|

| *PM6M | 0.004 | 0.1 | ||

| *PM22S | 0.01 | 0.25 | ||

| *PM21M | 0.005 | 0.13 | ||

| *PM0510 | 0.04 | 1 | ||

| *PM3010 | 0.04 | 1 | ||

| *PM5010 | 0.04 | 1 | ||

| *PM5030 | 0.118 | 3 | ||

| * Items currently stocked at Interstate | ||||

| * Pore size values are measured by Bubble Point and indicate the largest measured pore. Effective mean pore sizes will be lower than the stated value and will depend on the operating conditions. | ||||

* Items currently stocked at Interstate

* Pore size values are measured by Bubble Point and indicate the largest measured pore. Effective mean pore sizes will be lower than the stated value and will depend on the operating conditions.